3D

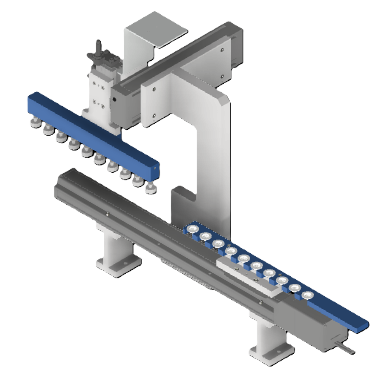

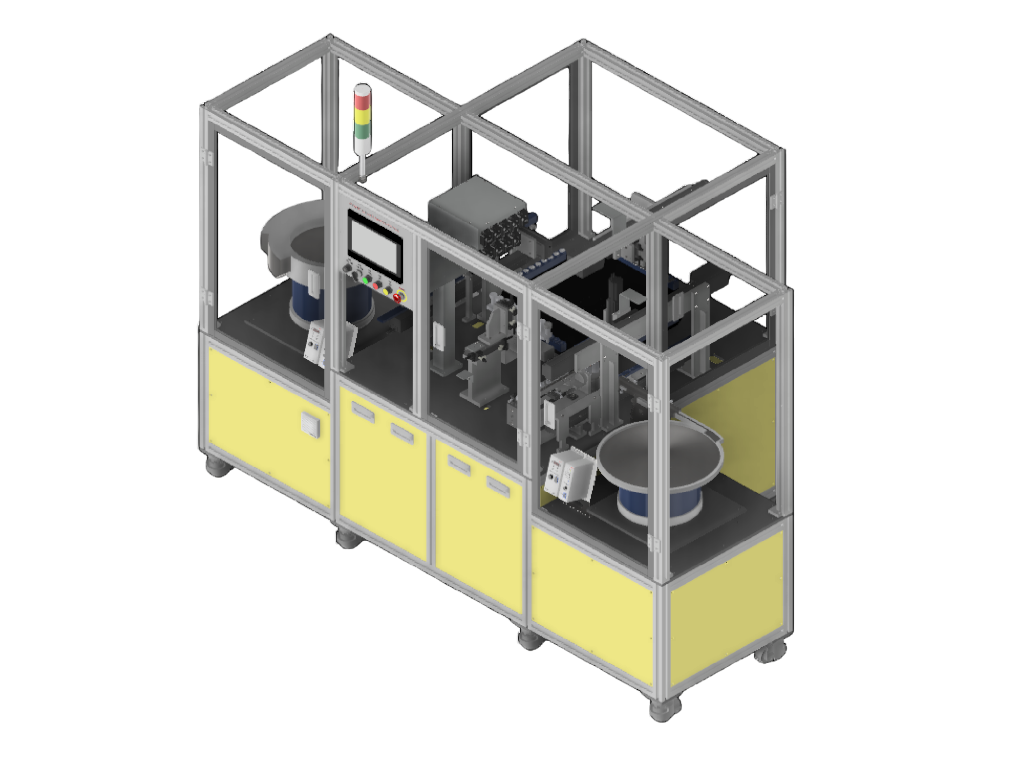

PP&PPT Assembly Machine

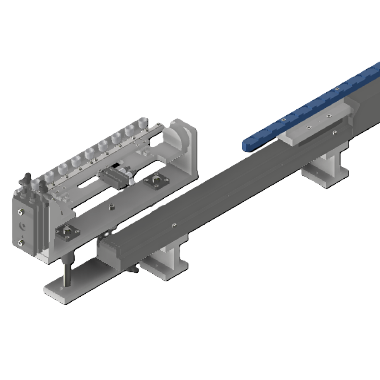

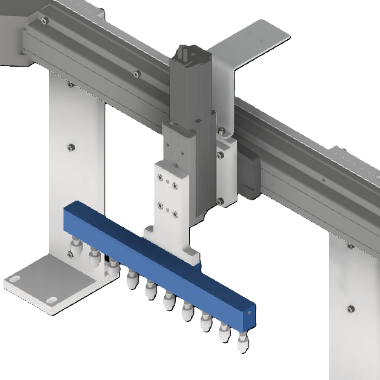

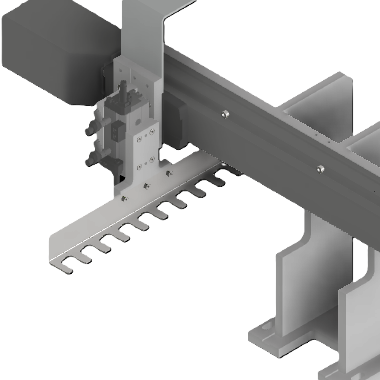

The lower mold supplied from the feeder is transferred by a servo. The transferred mold is placed on an indexer, filled with chemicals, rotated from the indexer to the upper mold, and then placed on standby. Furthermore, the upper mold supplied from the feeder is transferred by a servo. The transferred mold is rotated by a reverser, and the upper and lower molds are assembled. Finally, the assembled mold is Release into a drying oven..

-

60 per minute

-

Automated system

-

PLC Control

-

Touchscreen operation

Special feature

- Buzzer and stop when equipment is abnormal.

- Minimize product supply damage & defects.

- Automatic speed control possible using a servo motor.

- Using PLC programs.

Details

| Model | Len-3AL |

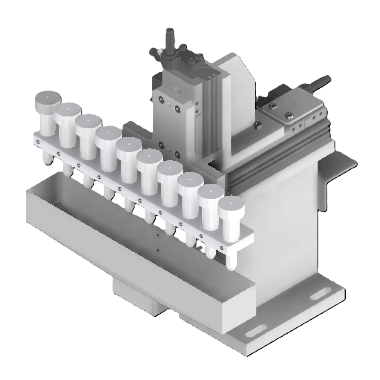

| Number of transfer molds | 10 Mold |

| Production capacity | 60 EA/min |

| Program | PLC & Servo Program |

| Power Consumption | 3kW |

🎬Machine Video

PP&PPT Lens Assembly

PP&PPT Lens Assembly

PP&PPT Lens Assembly Touch Screen