3D

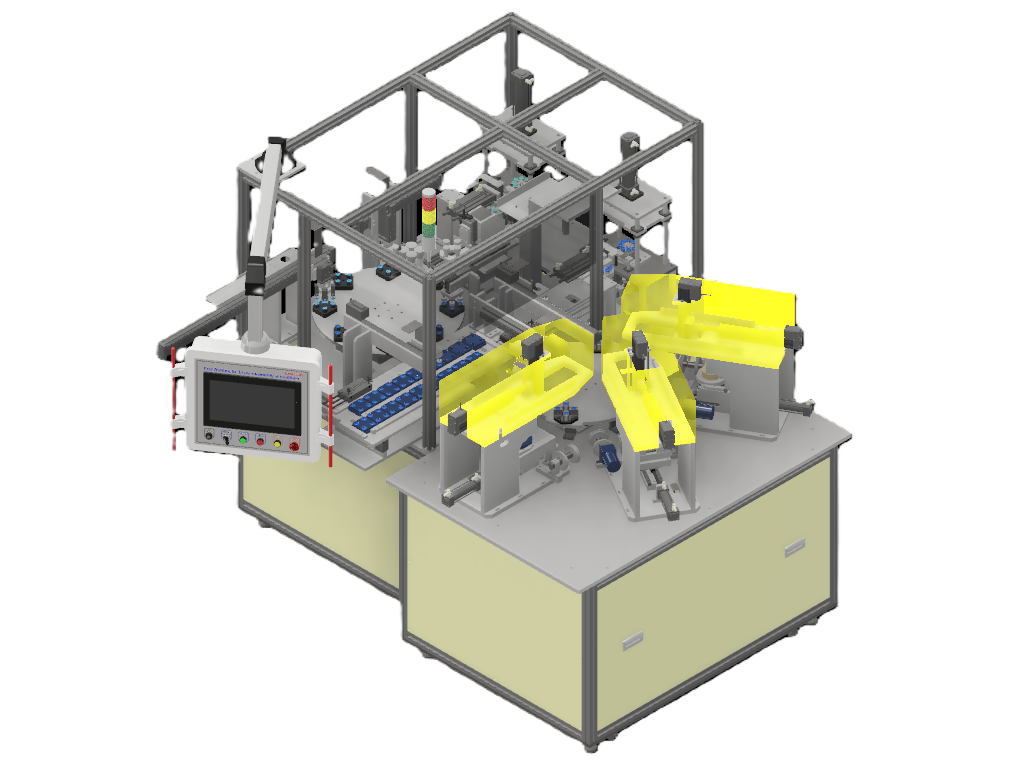

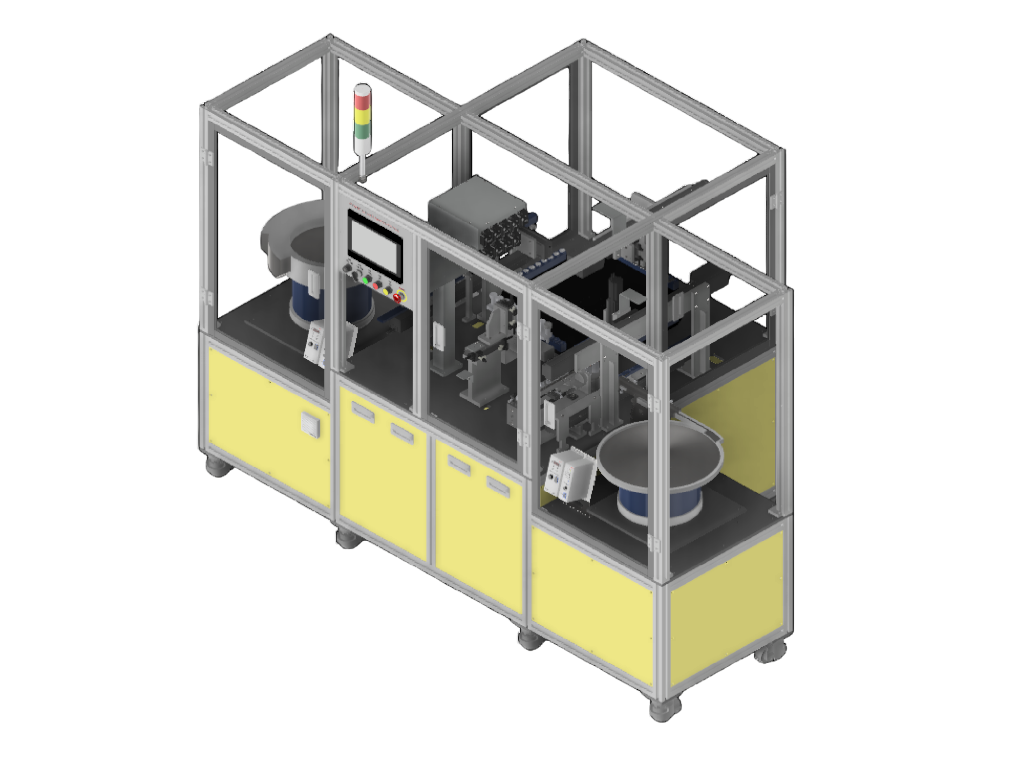

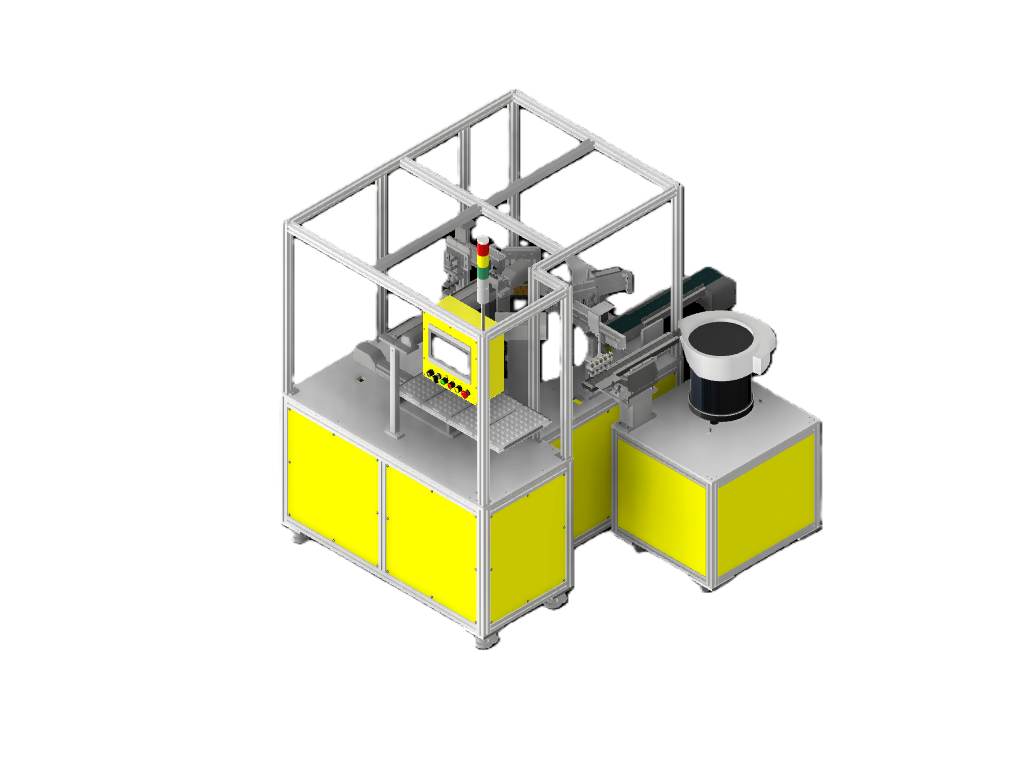

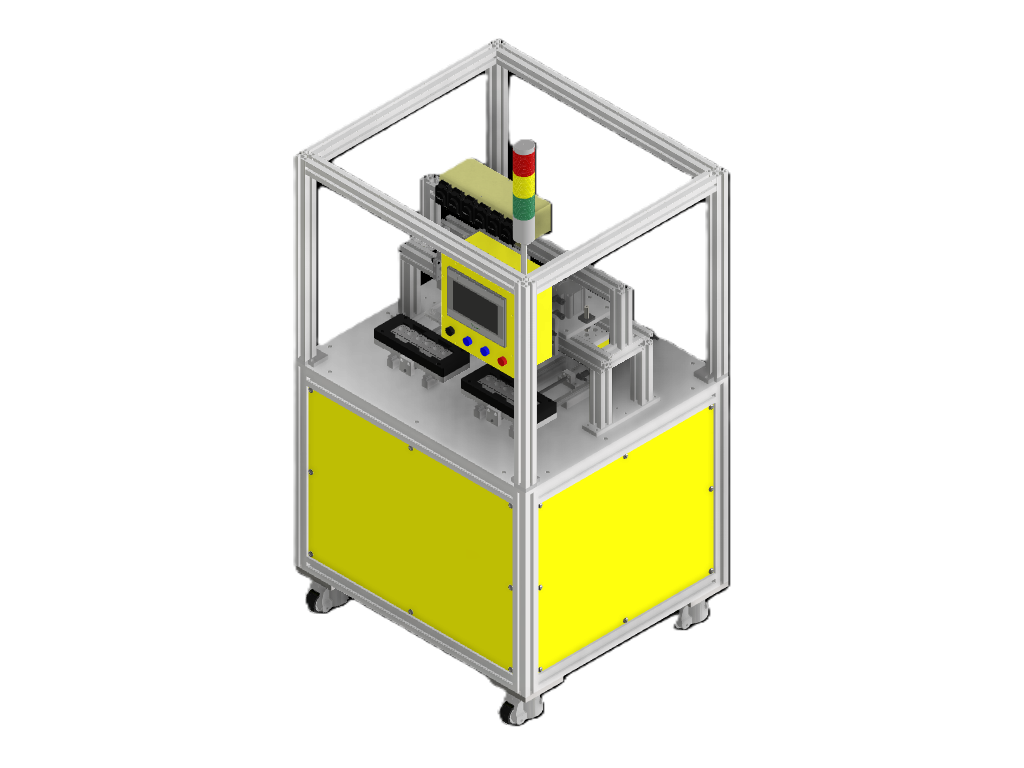

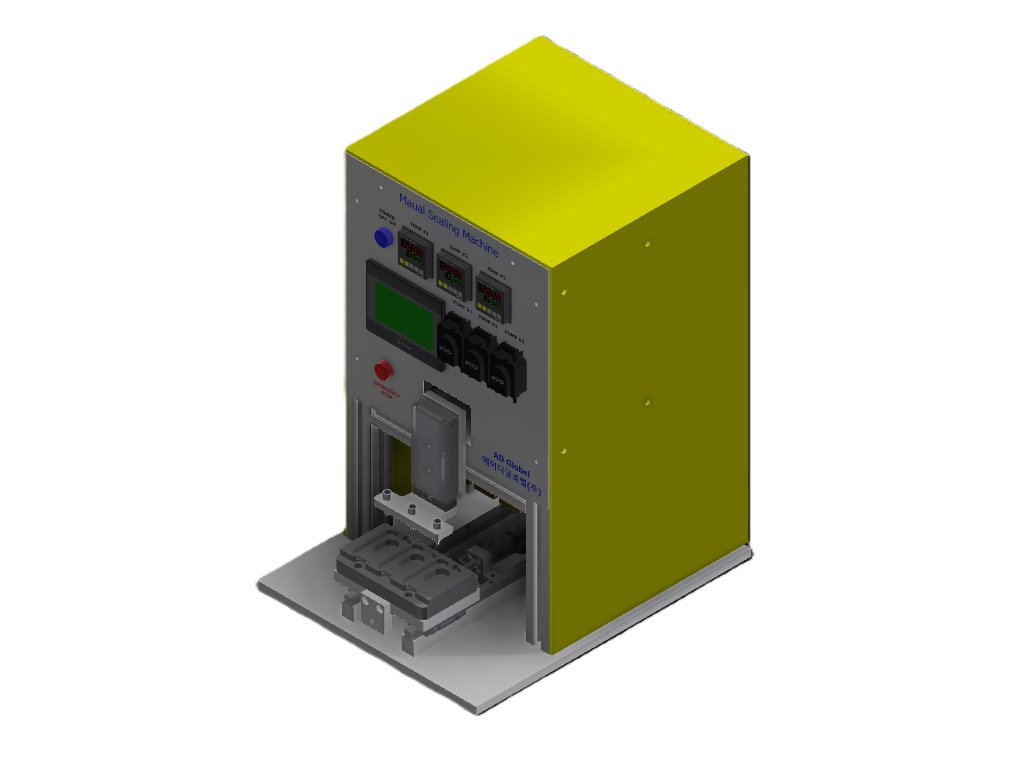

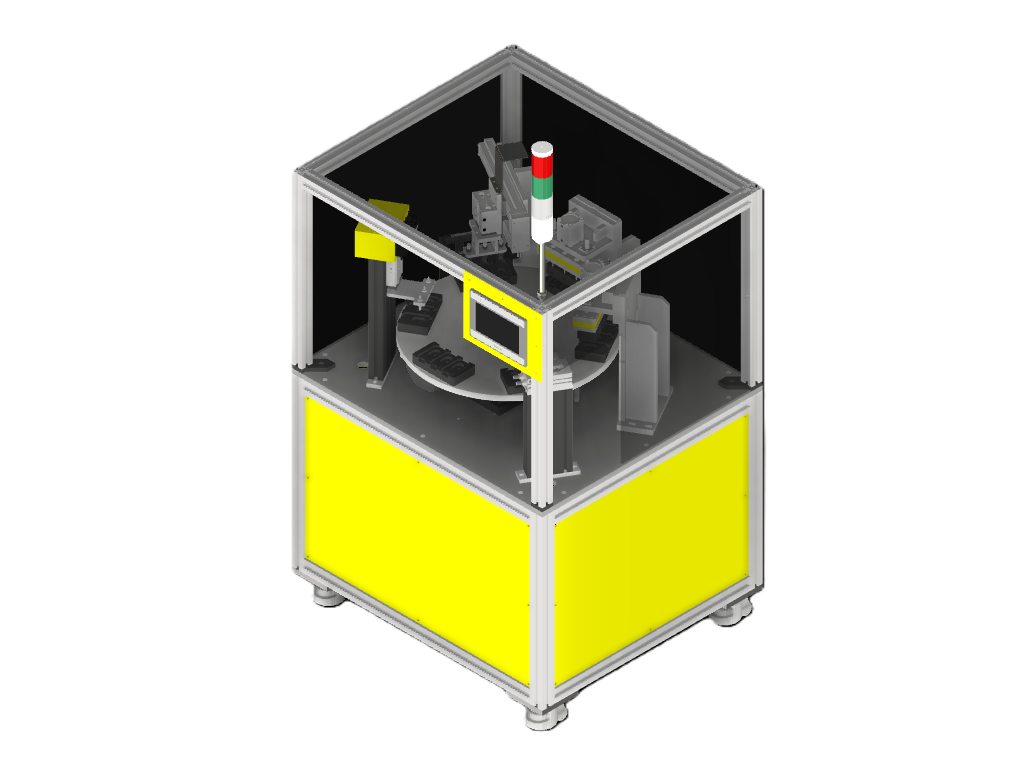

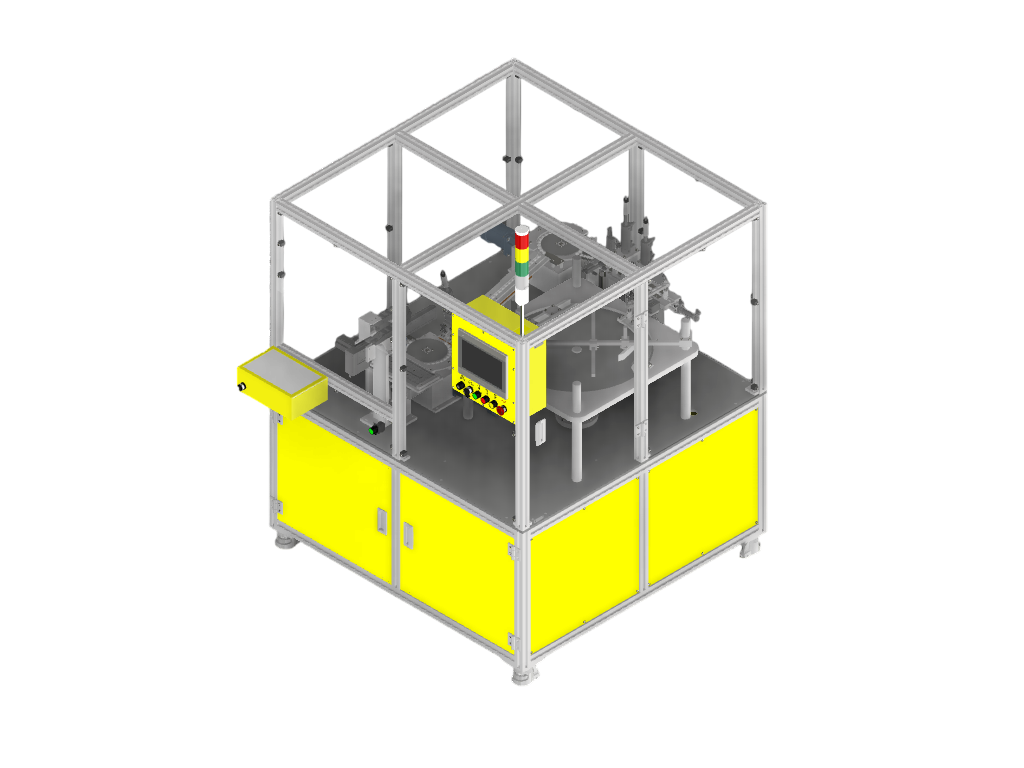

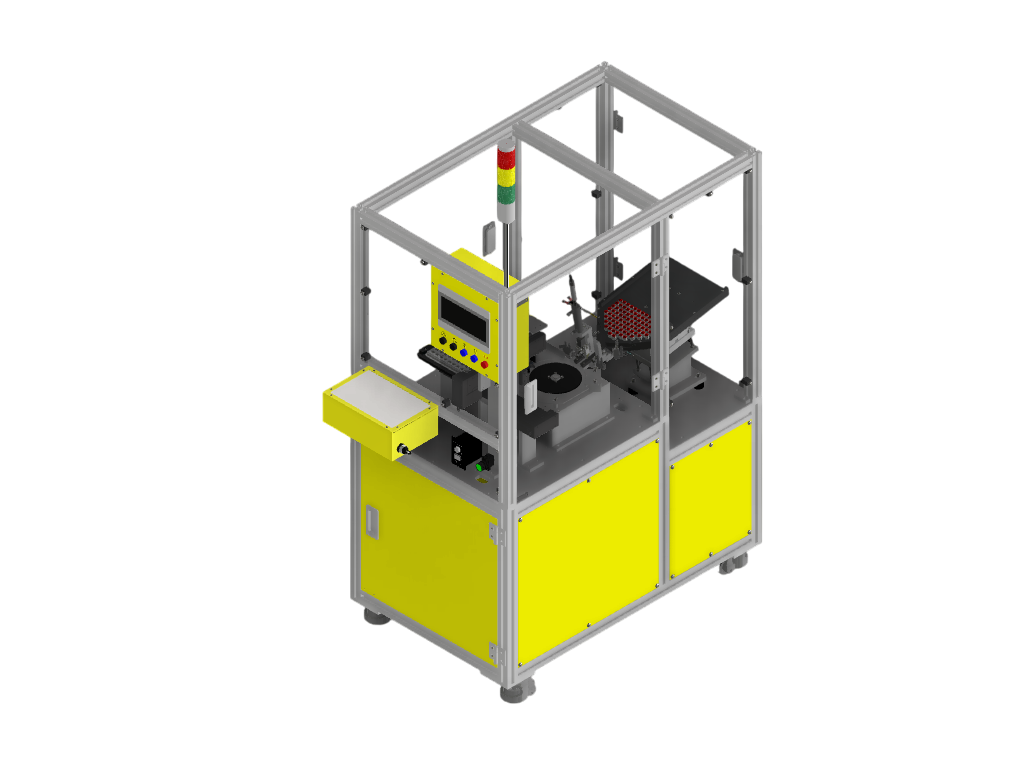

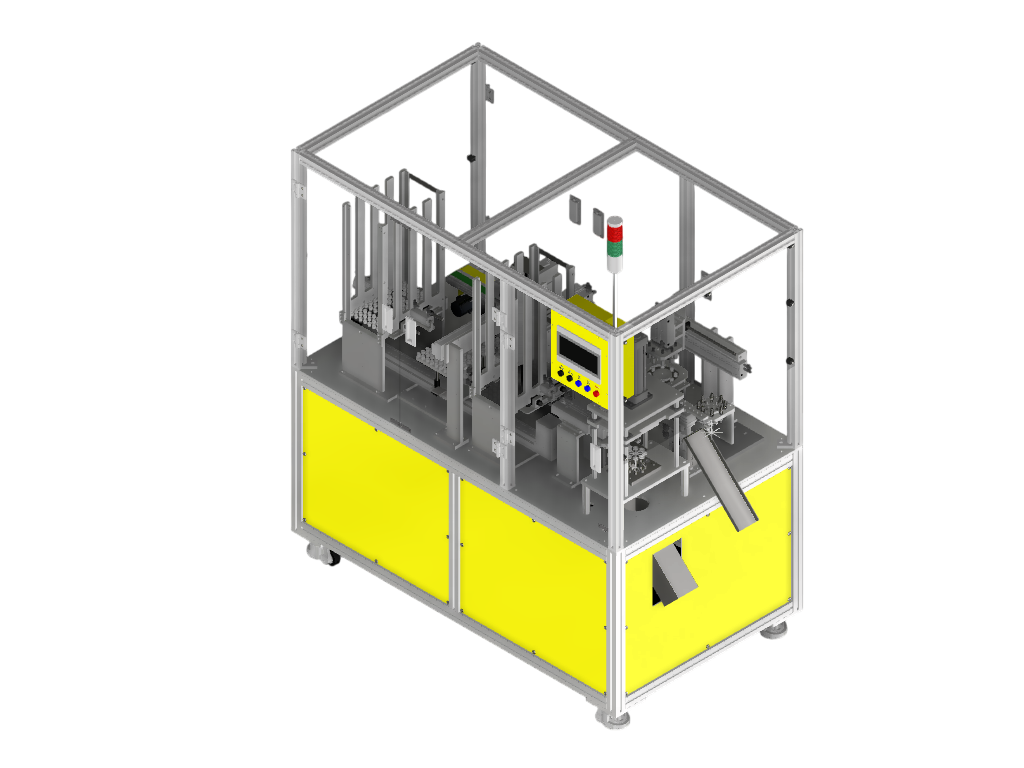

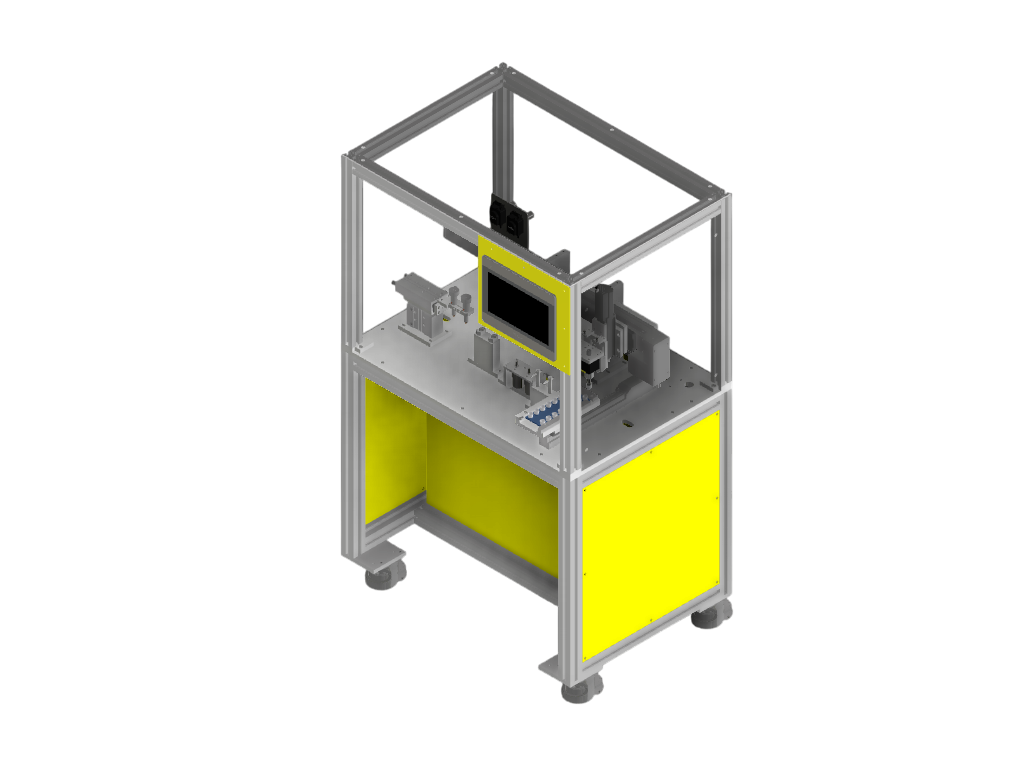

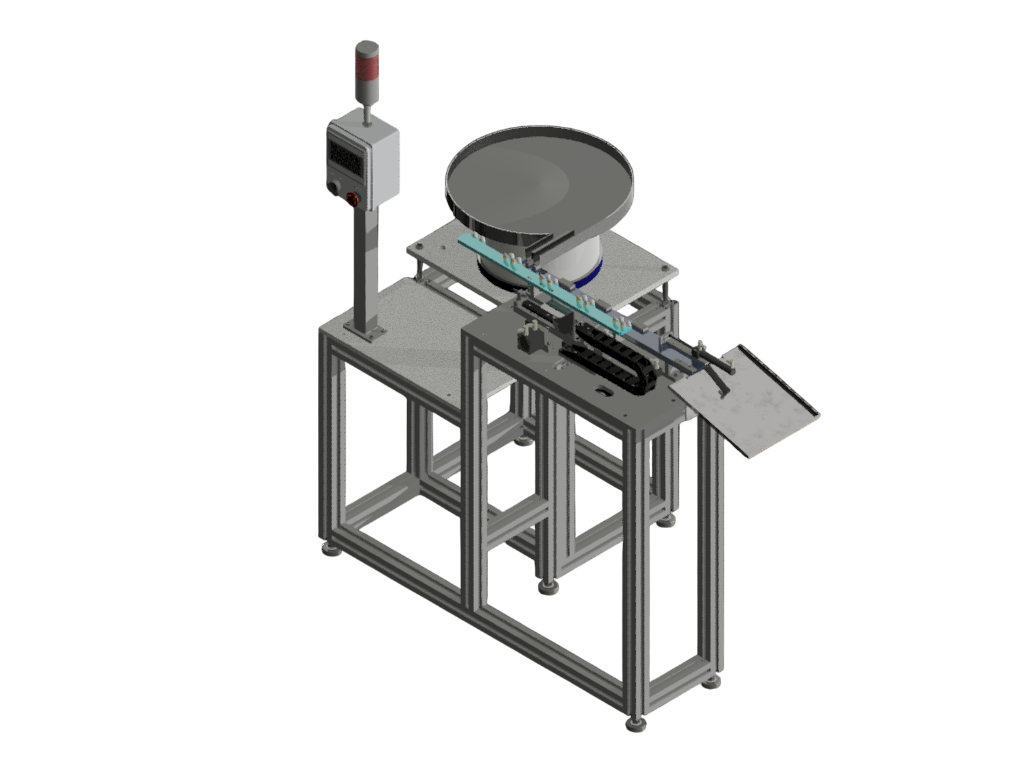

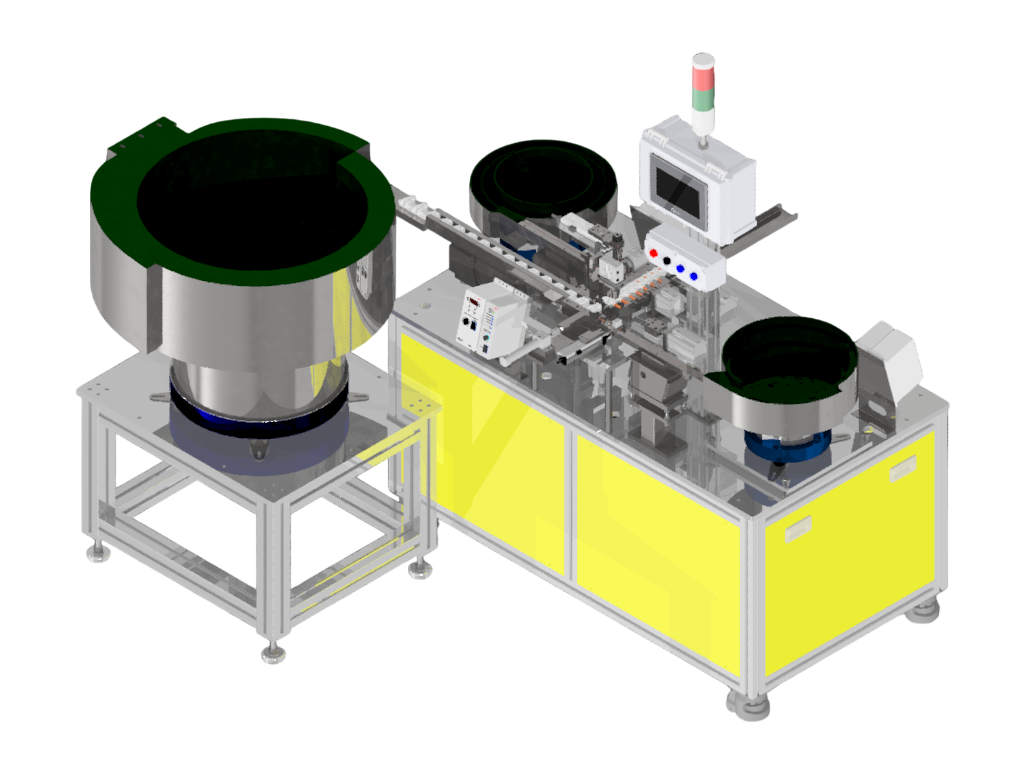

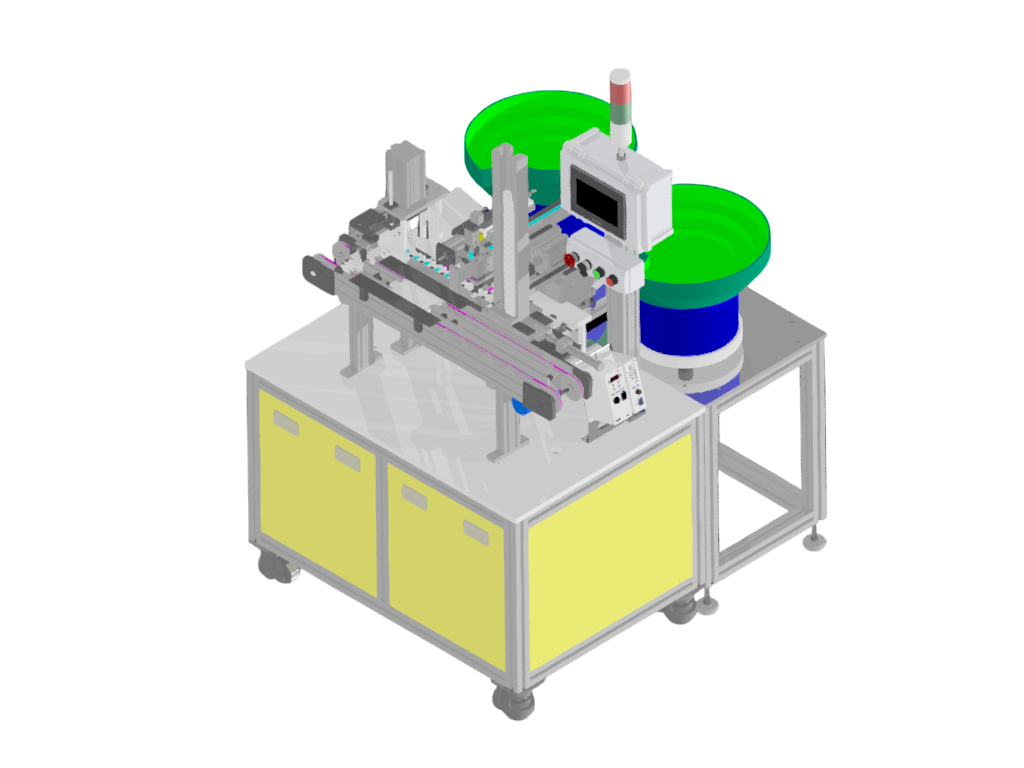

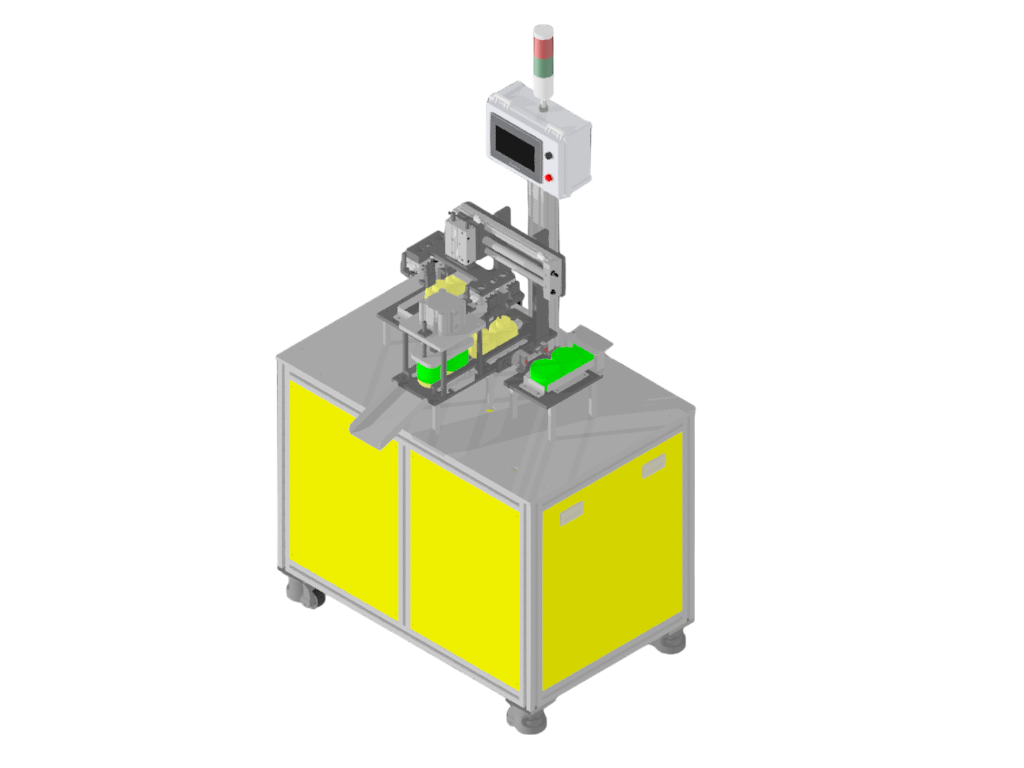

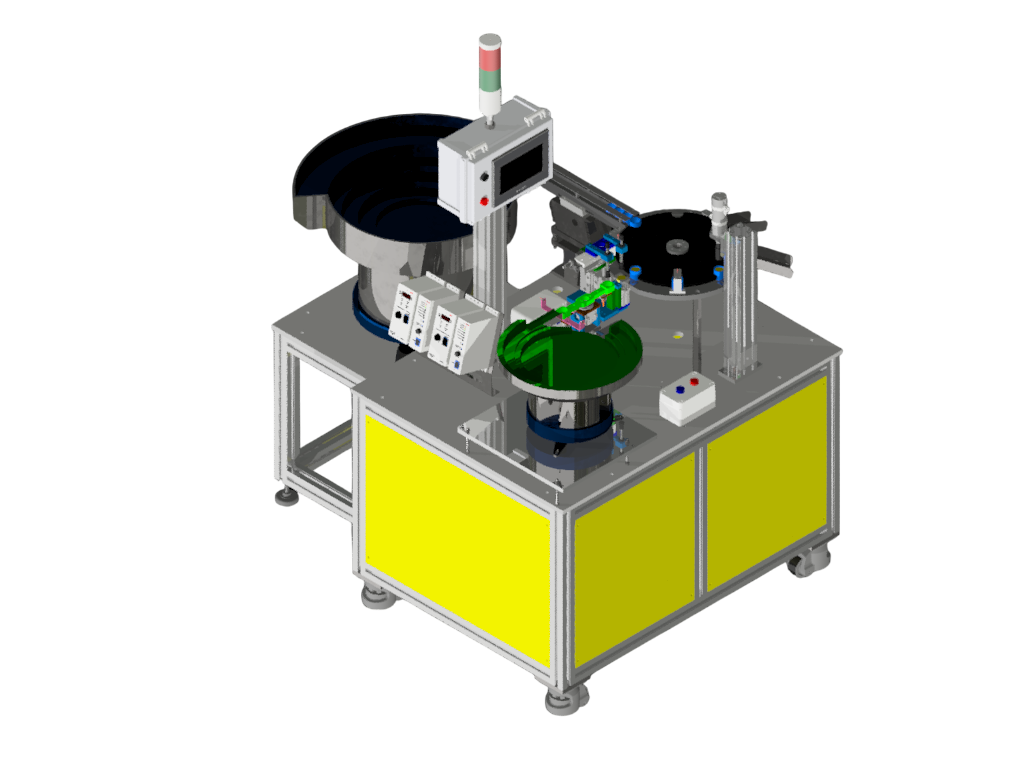

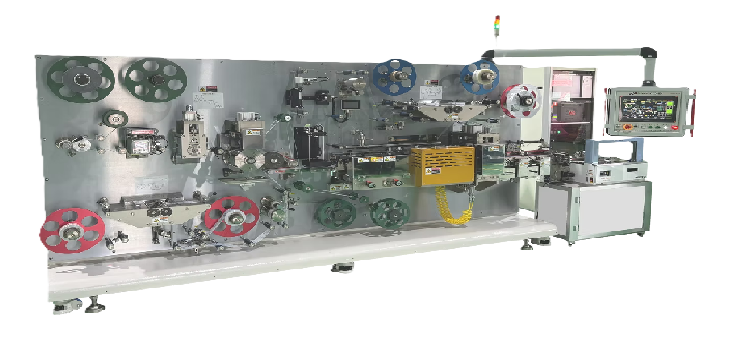

Asthma Patch Manufacturing Machine

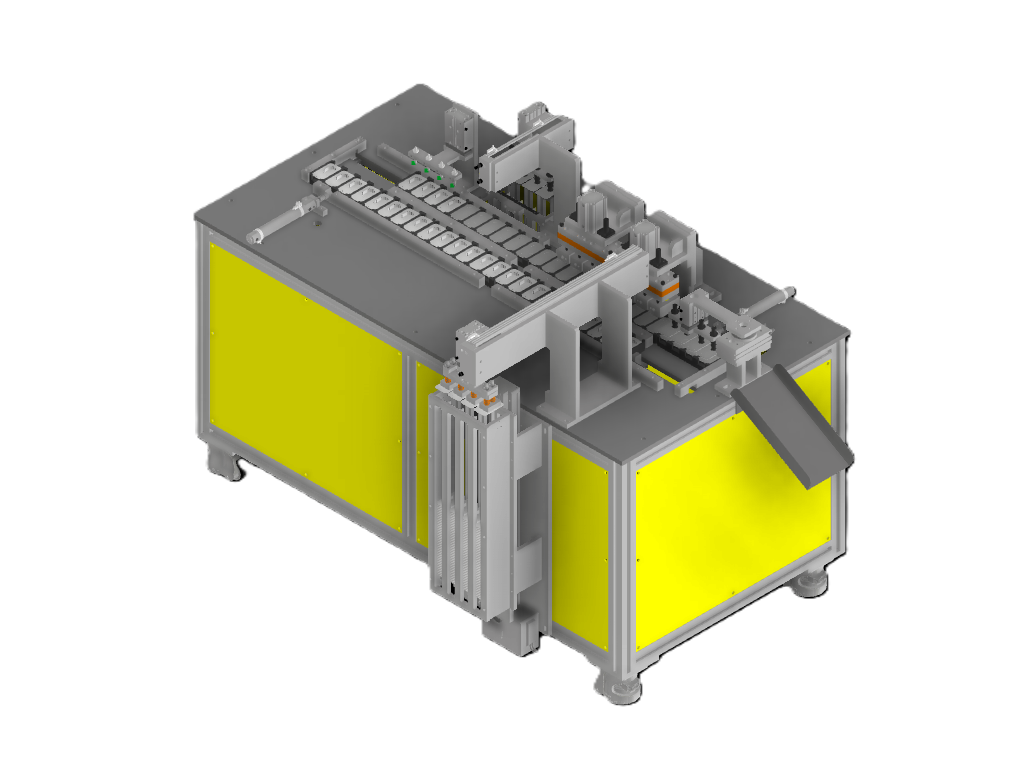

This is a device that receives materials, cuts them to the set dimensions, determines whether the product is in good condition, puts the genuine product into a packaging machine, seals, cuts, and discharges the finished product by banding it.

-

250 per minute

-

Automatic system

-

Plc & Motion control

-

Touchscreen operation

-

Vision PC control

Special feature

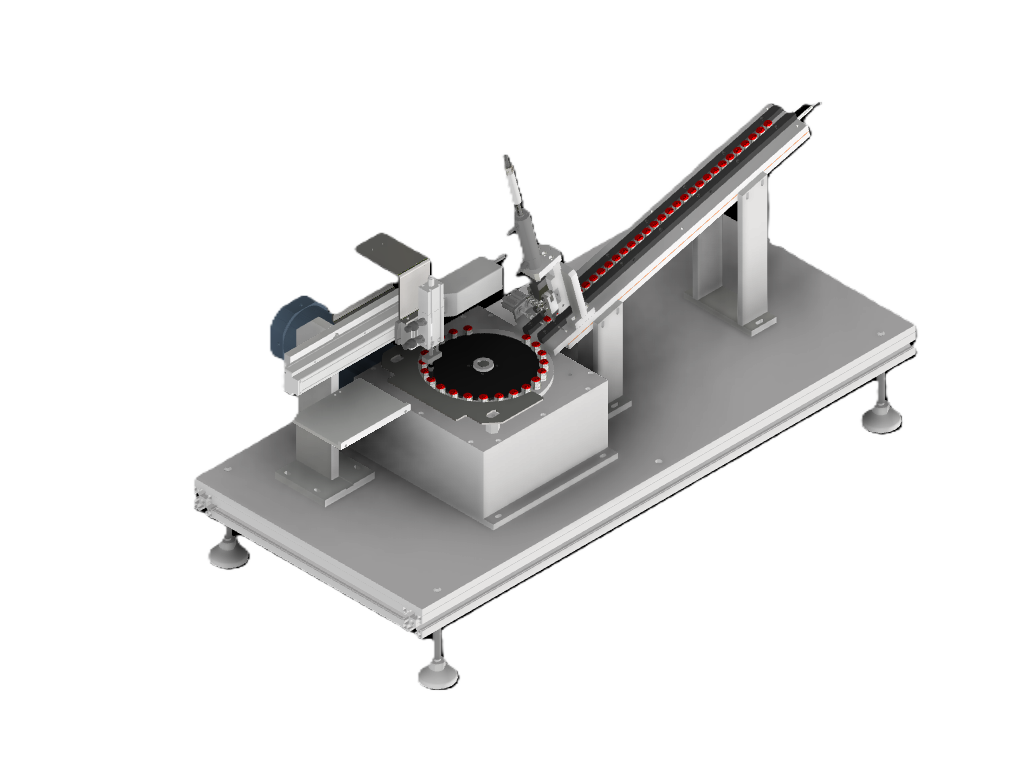

- Automatic control provides a certain amount of fabric and maintains tension.

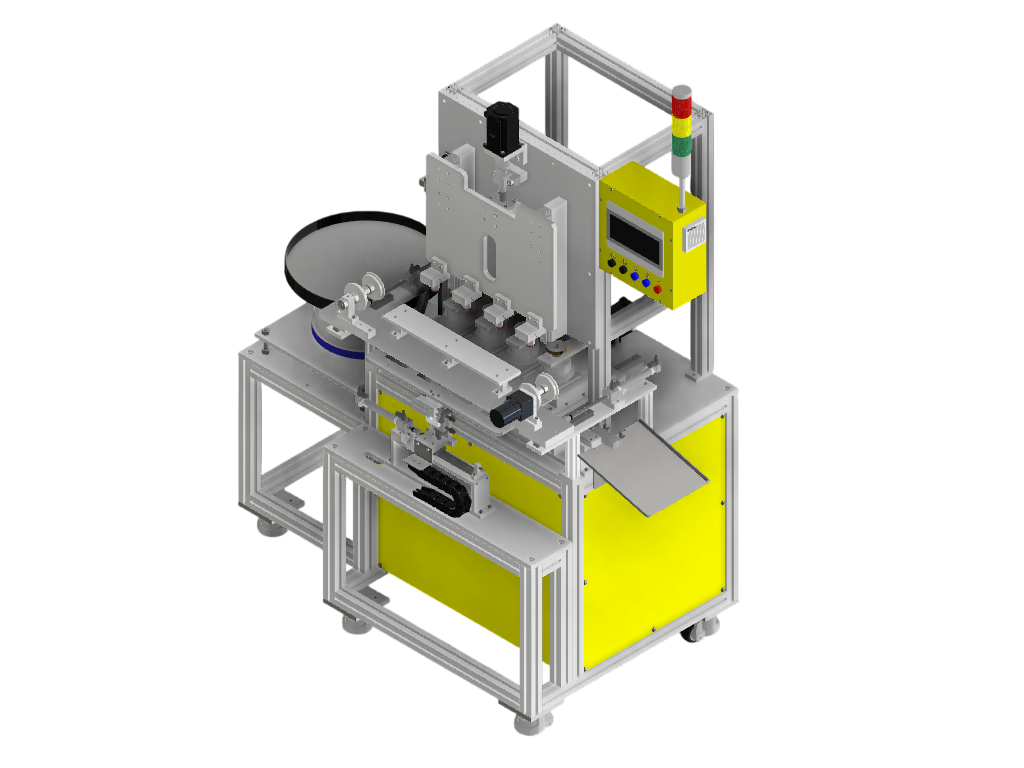

- Accurate length transfer is possible with the use of vacuum feeding rollers.

- Shape can be changed by rotary blade replacement.

- You can adjust the cutting length of the outer packaging paper by using the servo motor.

- Rotary format to minimize load and increase productivity.

- Using servomotors and motion programs.

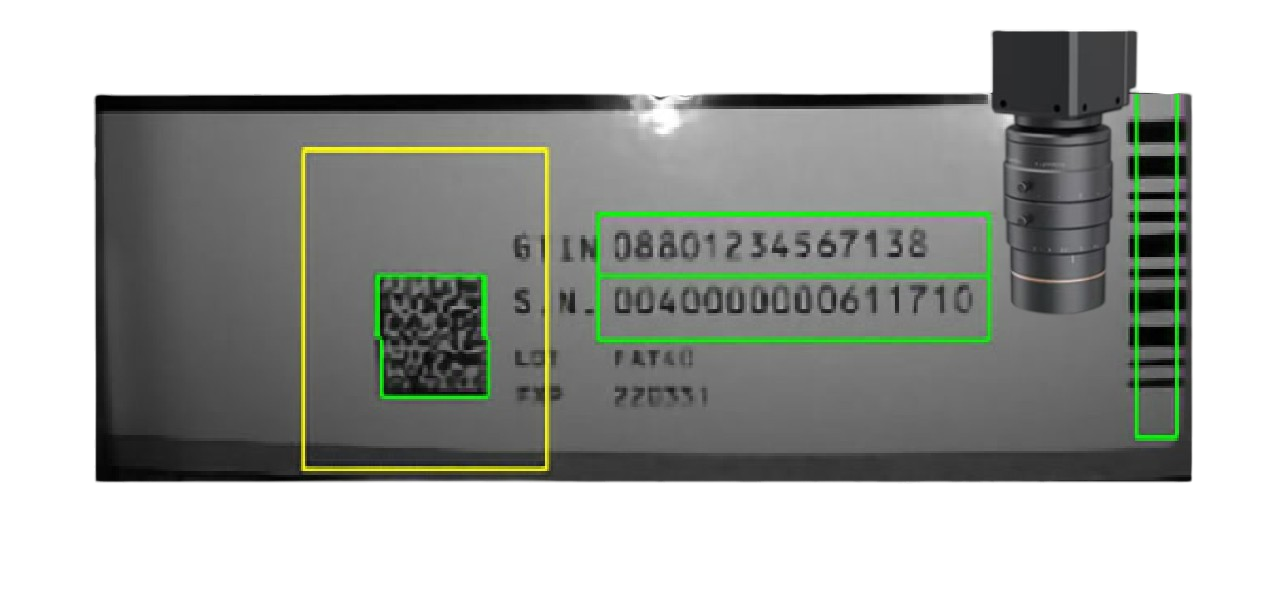

- Foreign body inspection (vision) system.

- Automatic process speed adjustment according to production quantity.

- Finished product coefficient and alignment, bendable.

Details

| Model | NPP-3000 |

| Cutting heat | 1 row |

| Production capacity | 250 EA/min (per column, including vision inspection) |

| External dimensions | 4500L x 1200W x 2000H (mm)*Custom-made |

| Cut form | Optional (R-cutting of finished product possible) |

| Program | PLC & servoProgram |

| Power Consumption | 12kW |

🎬Machine Video

Asthma patch manufacturing machine

Asthma patch manufacturing machine Touch