3D

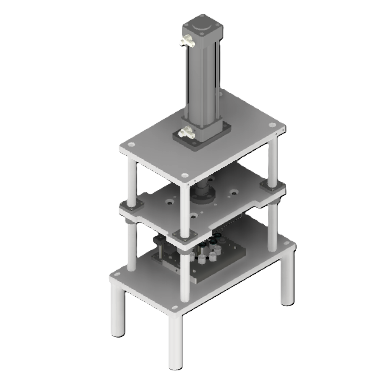

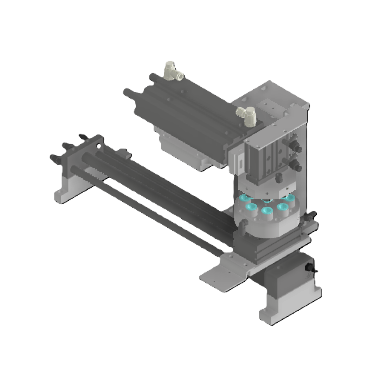

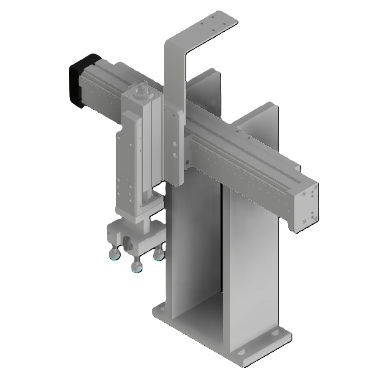

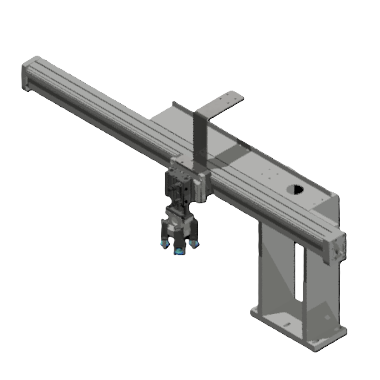

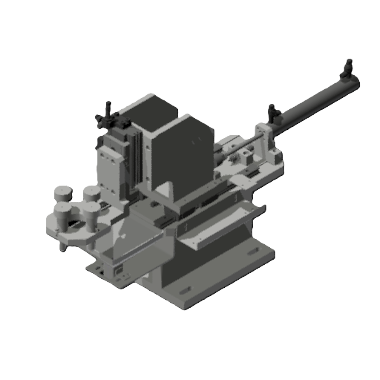

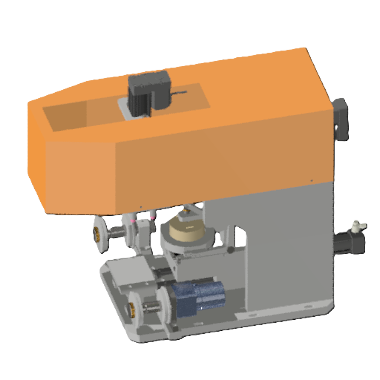

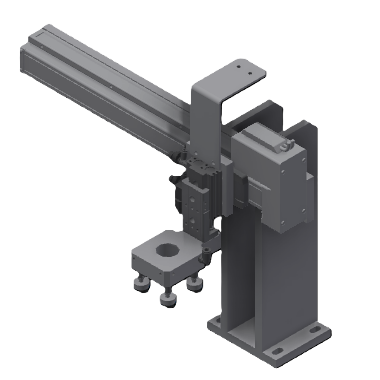

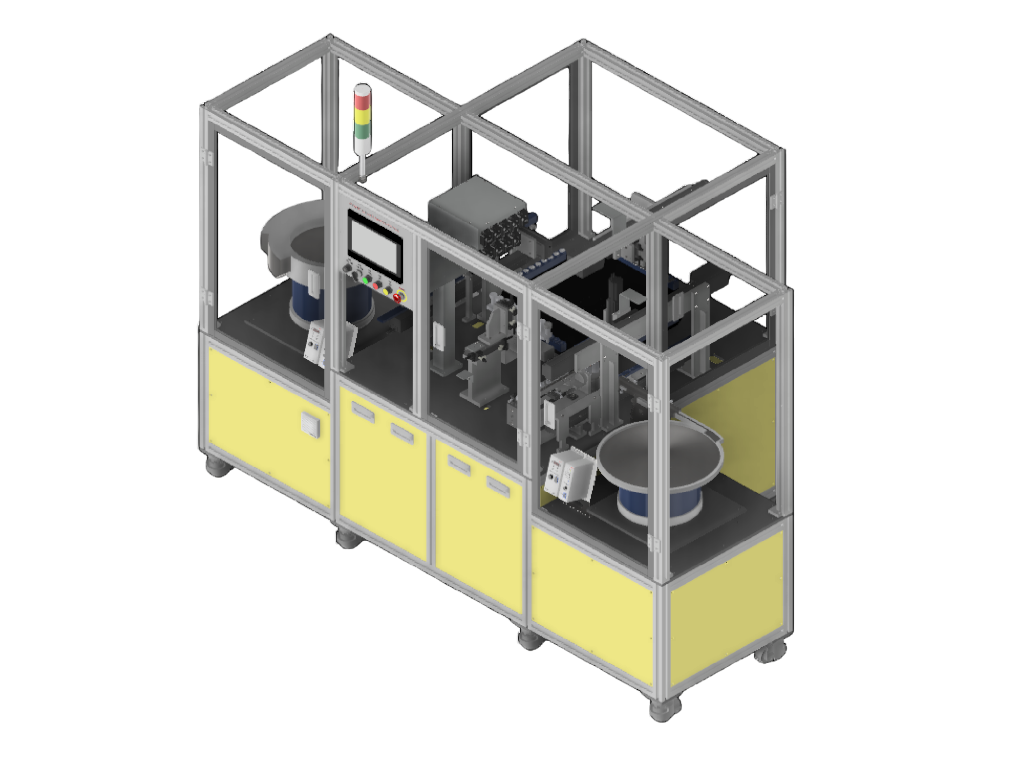

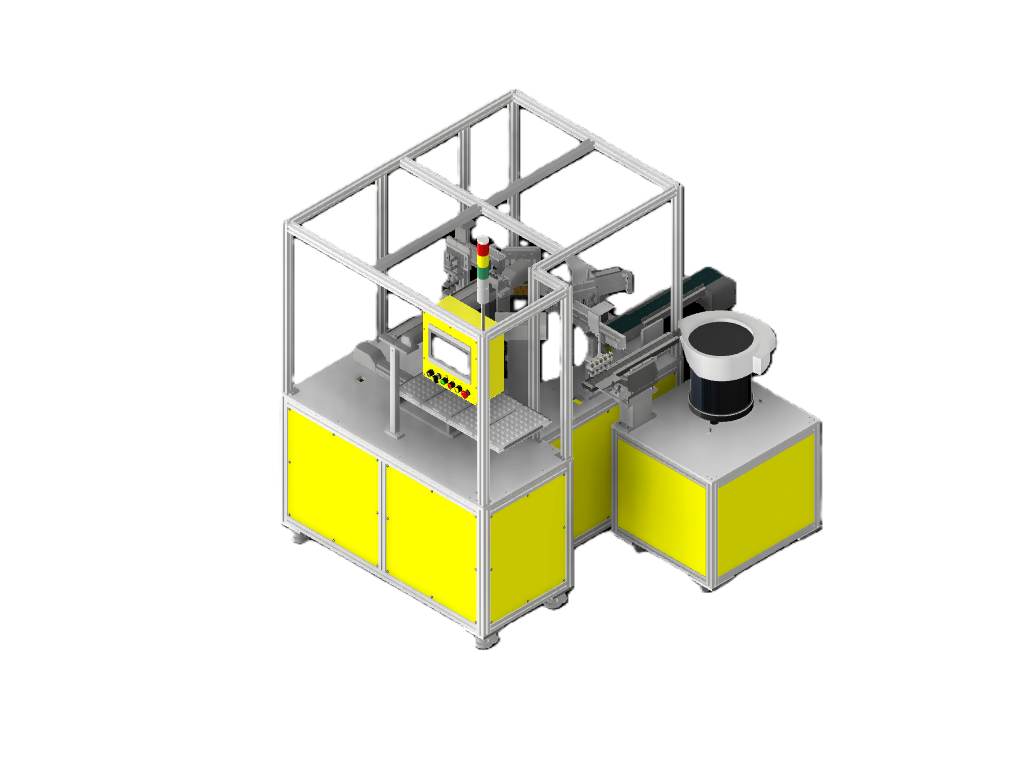

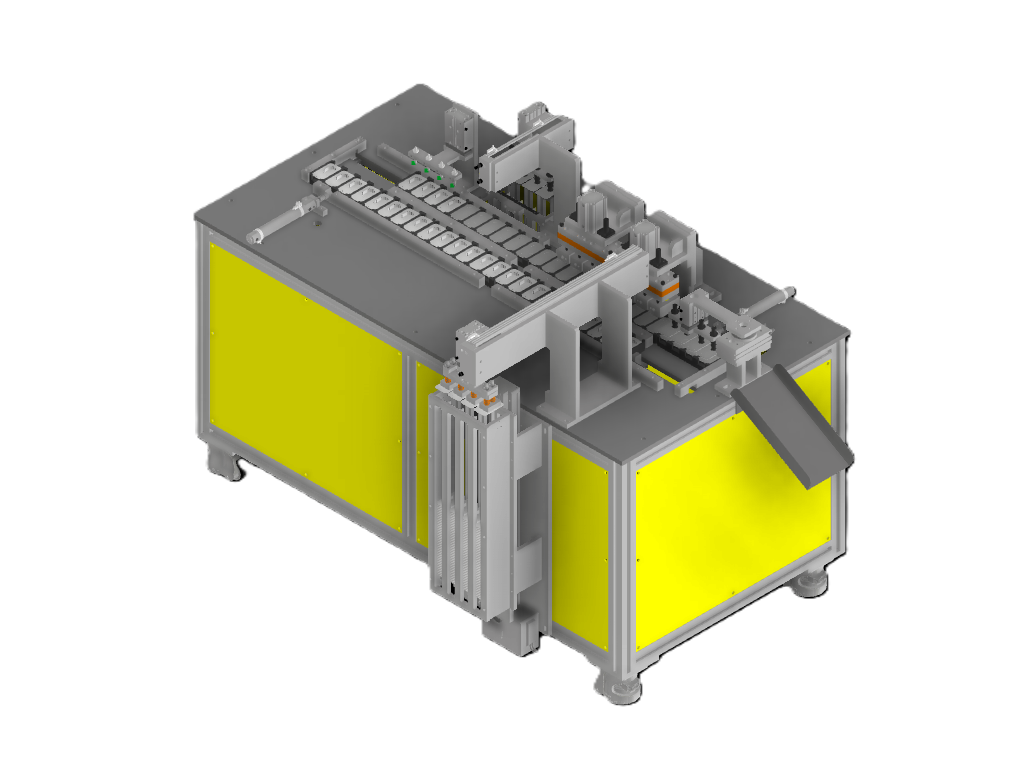

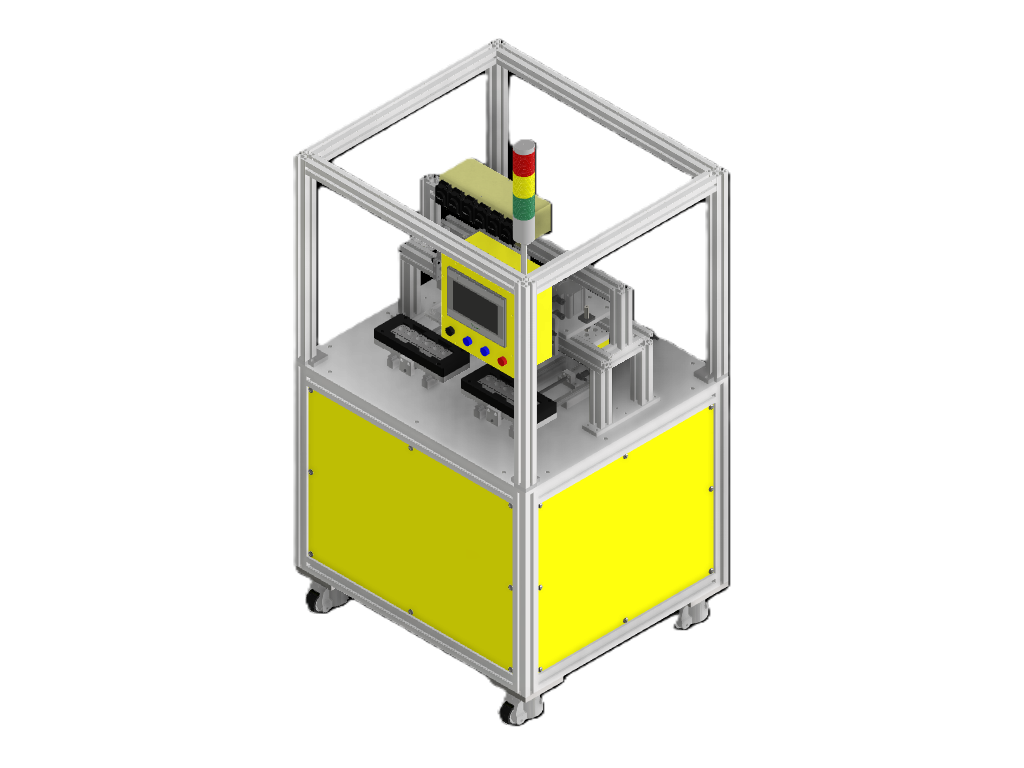

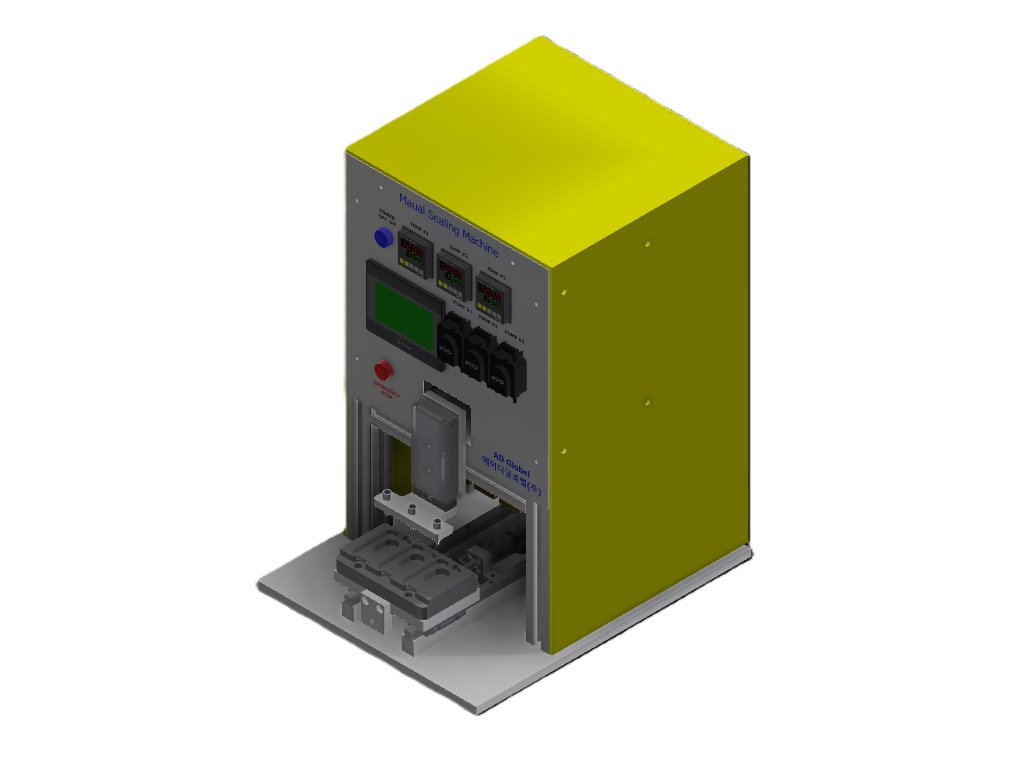

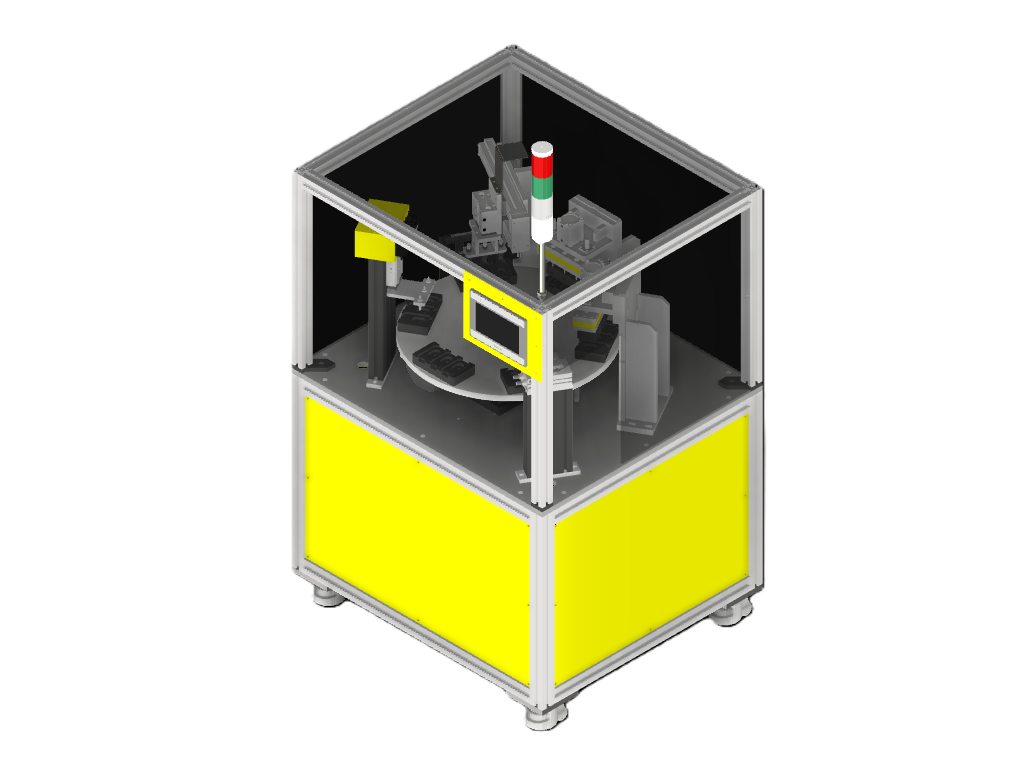

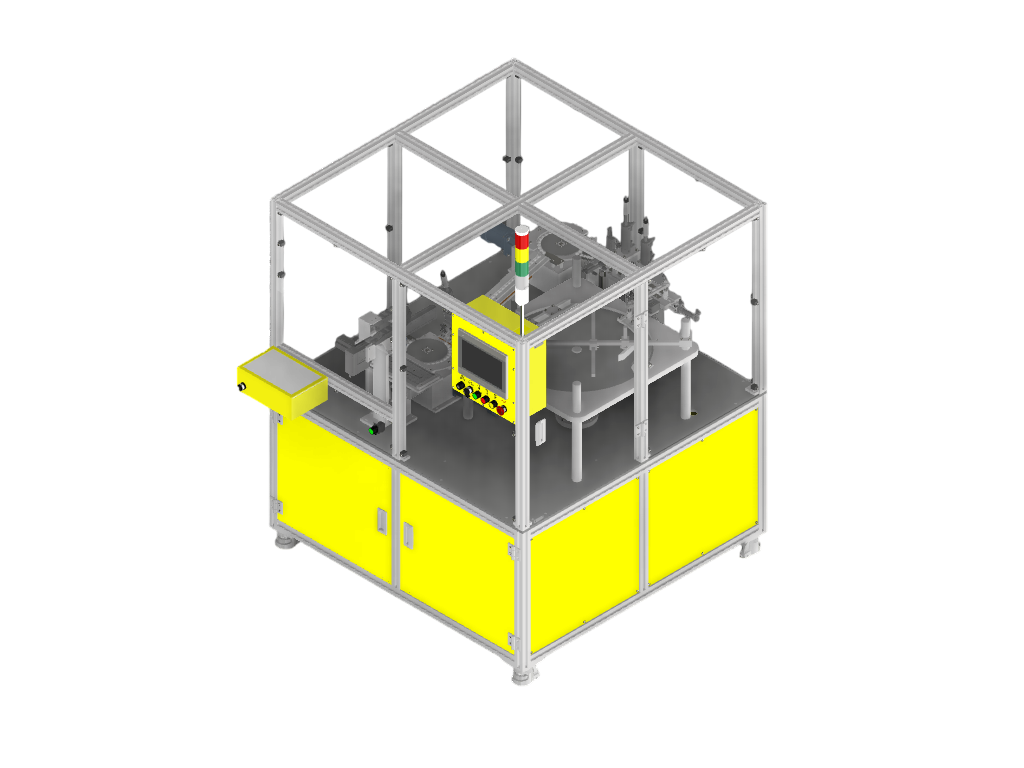

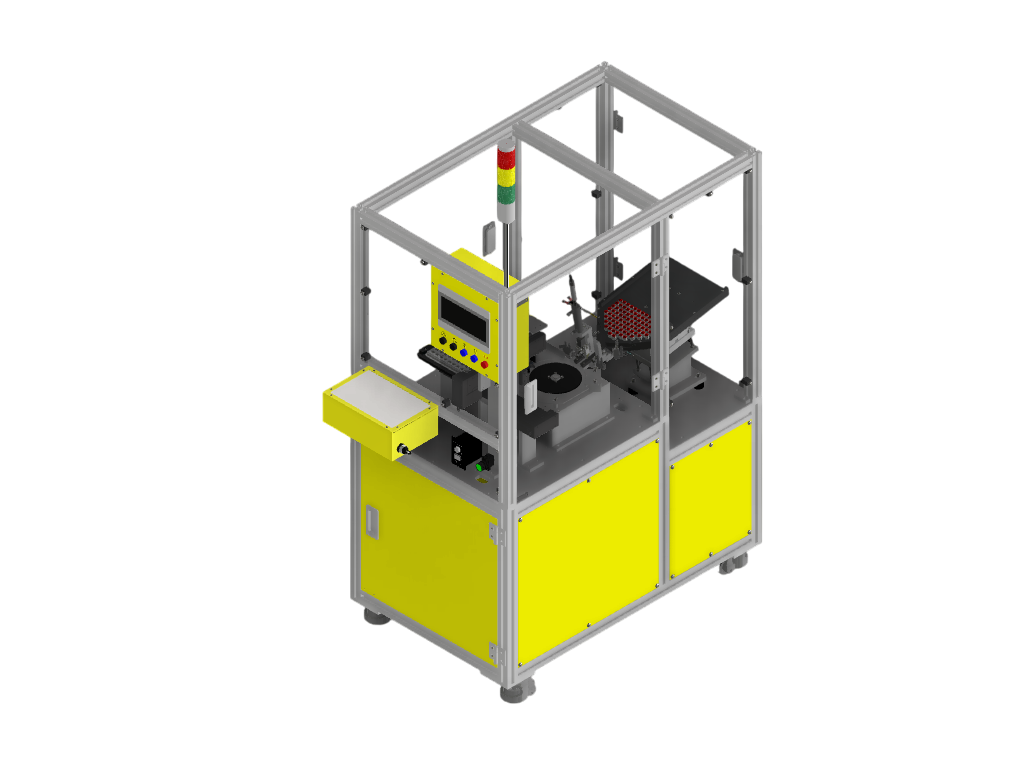

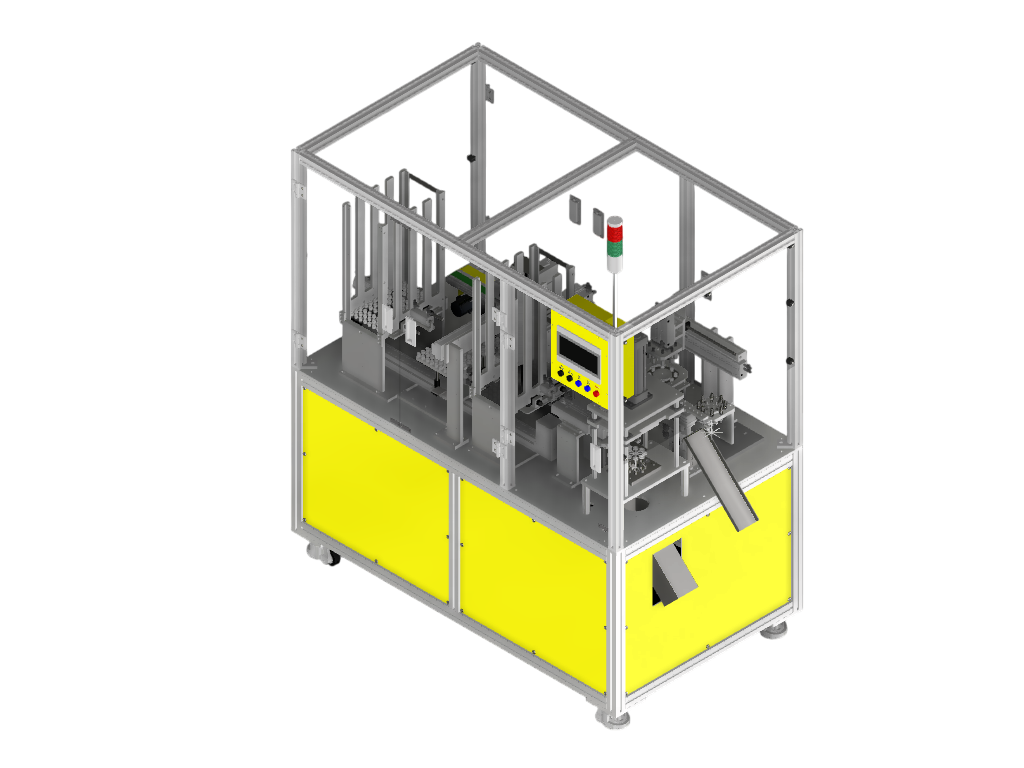

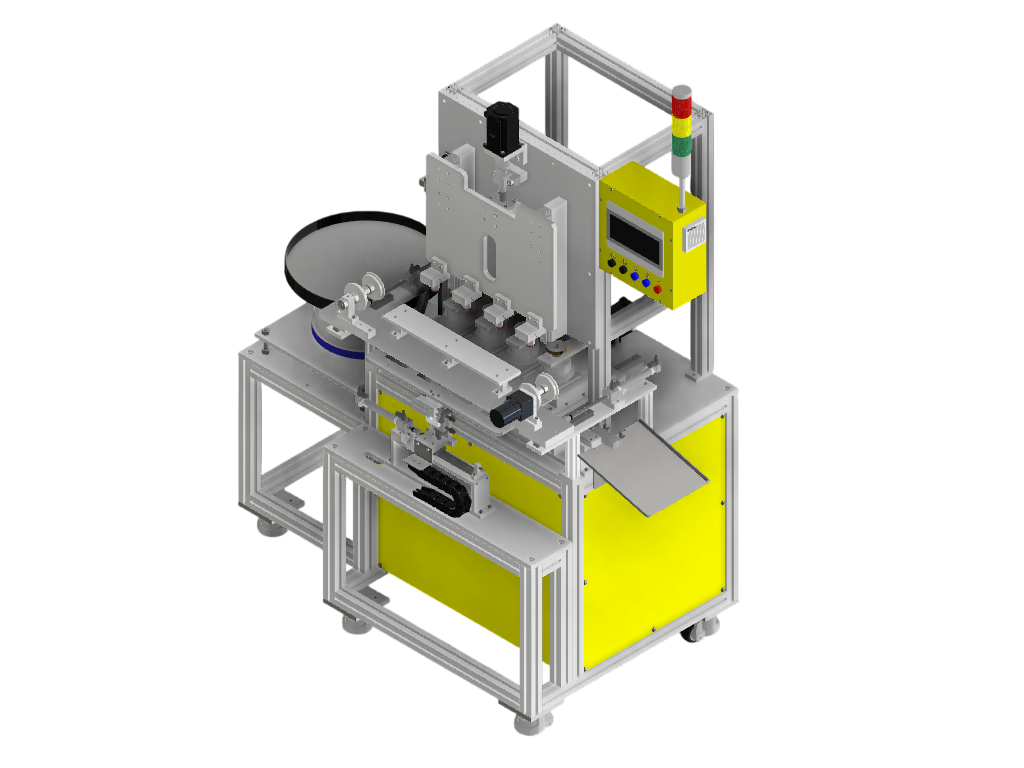

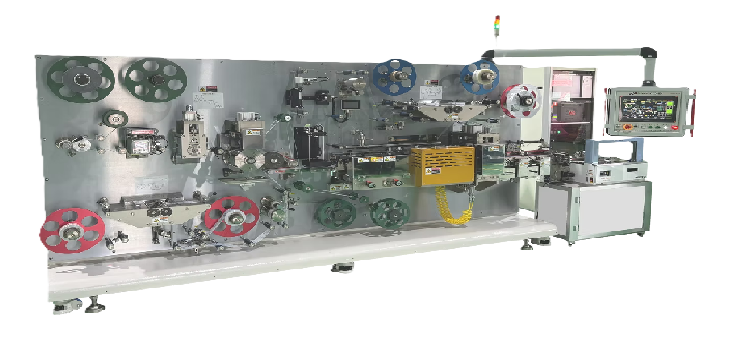

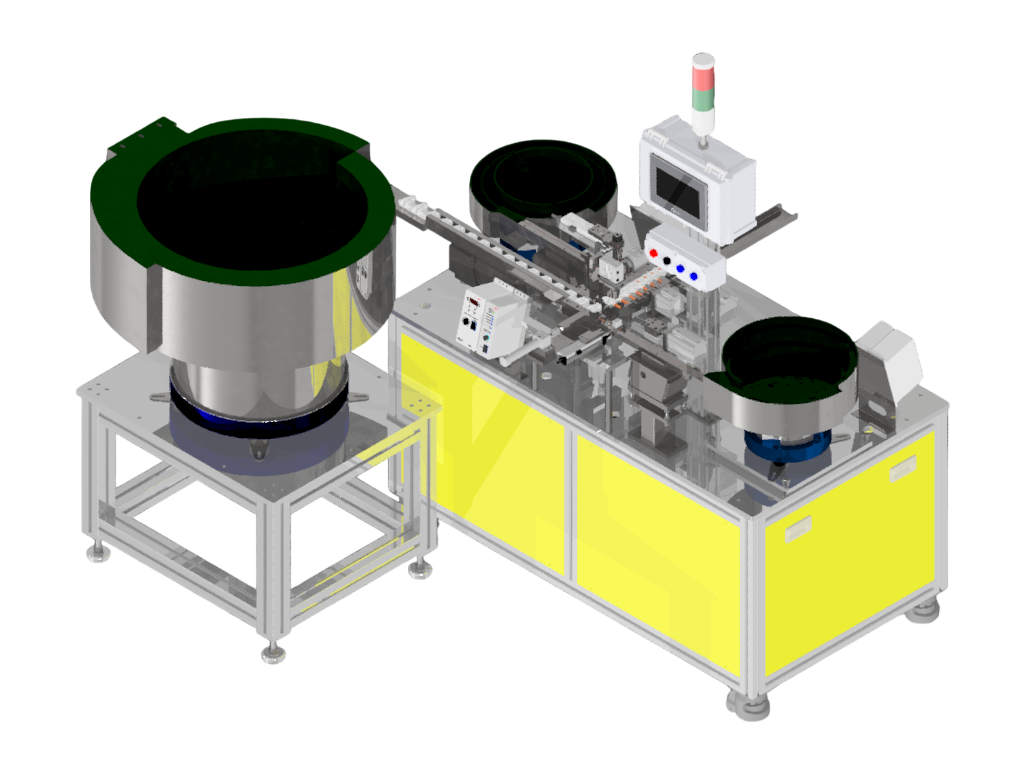

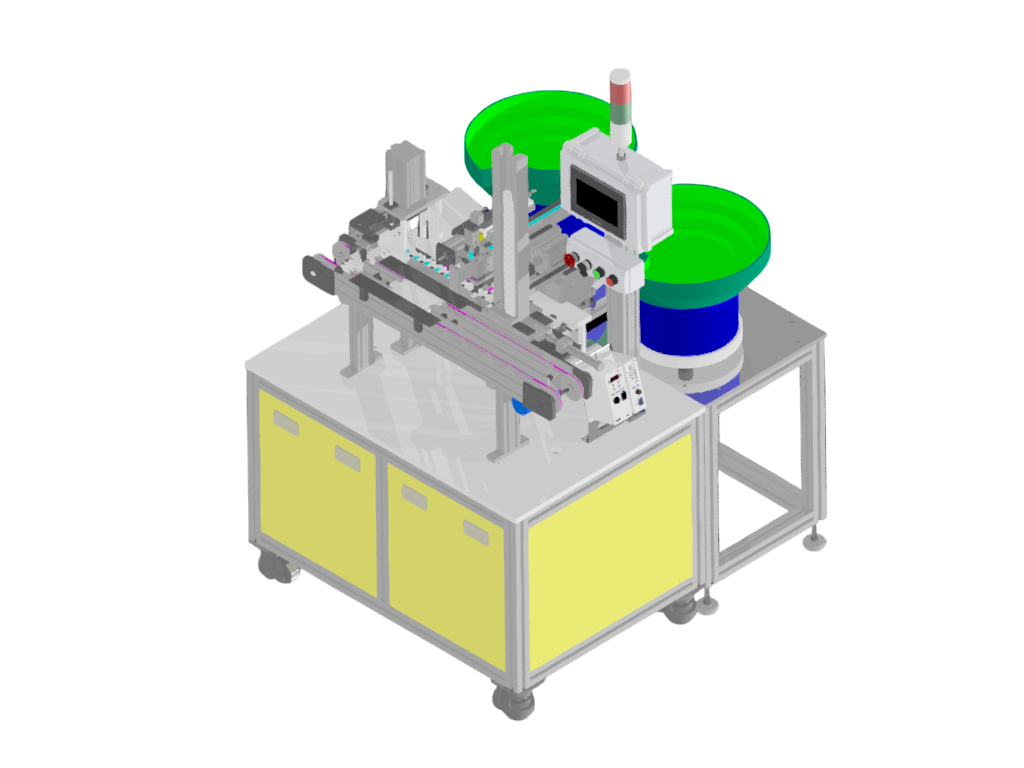

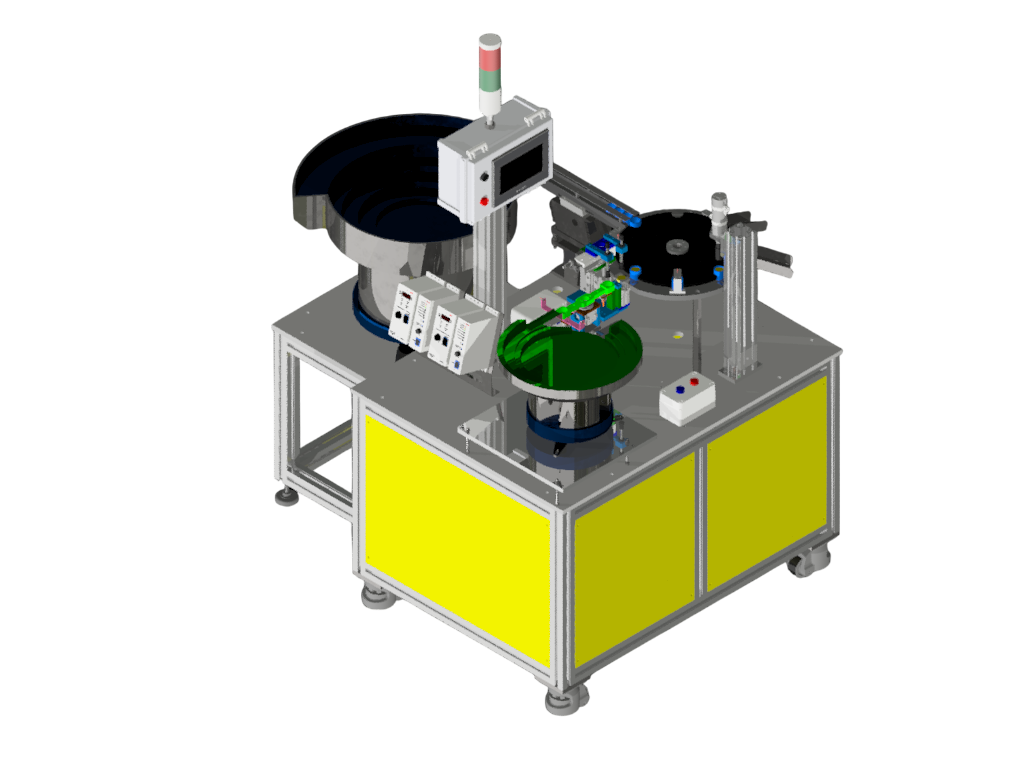

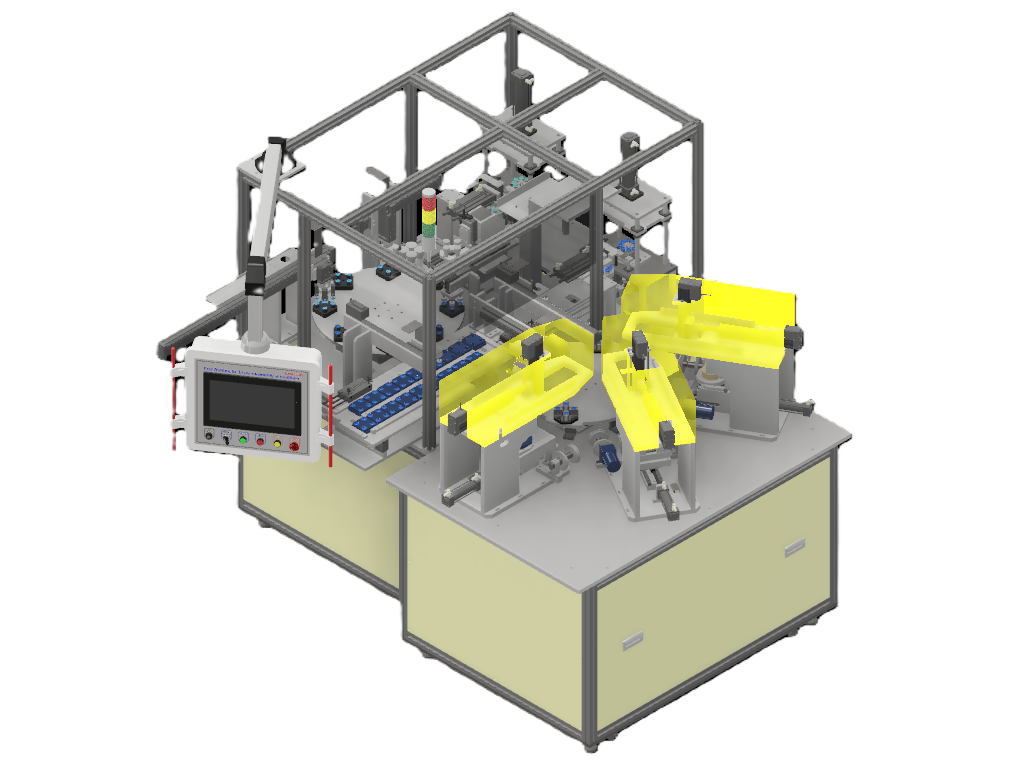

PP Assembly & Print Machine

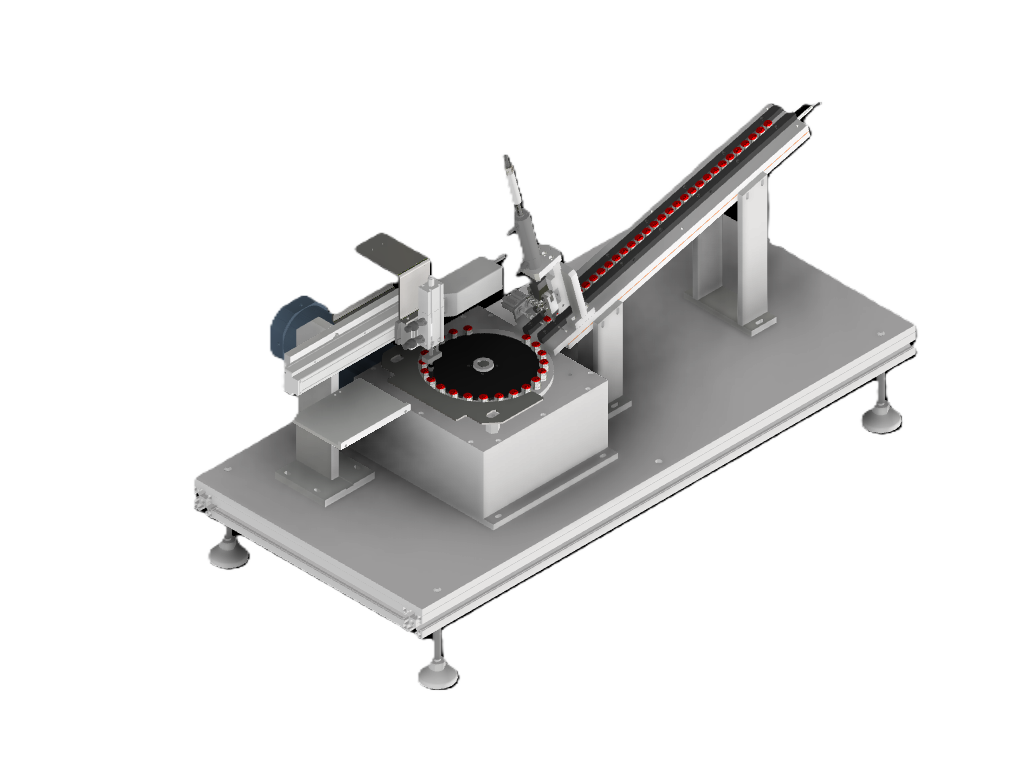

The injected lower mold is transferred to the cutting unit for cutting. It is then transferred to a color printer for color printing. Afterwards, the cut upper and lower molds are assembled through a chemical injection process. The assembled molds are then release from the dryer.

-

16 per minute

-

Automated system

-

PLC Control

-

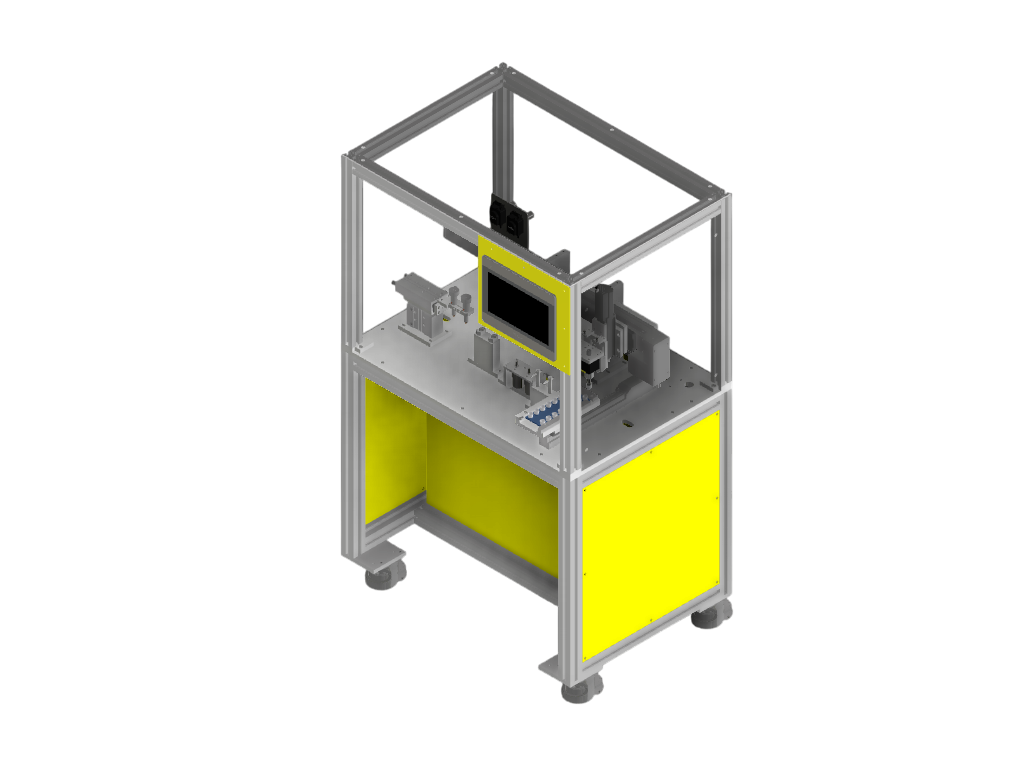

Touchscreen operation

-

Injection M/C Interlock

-

Robot Interlock

Special feature

- Buzzer and stop when equipment is abnormal.

- Minimize product supply damage & defects.

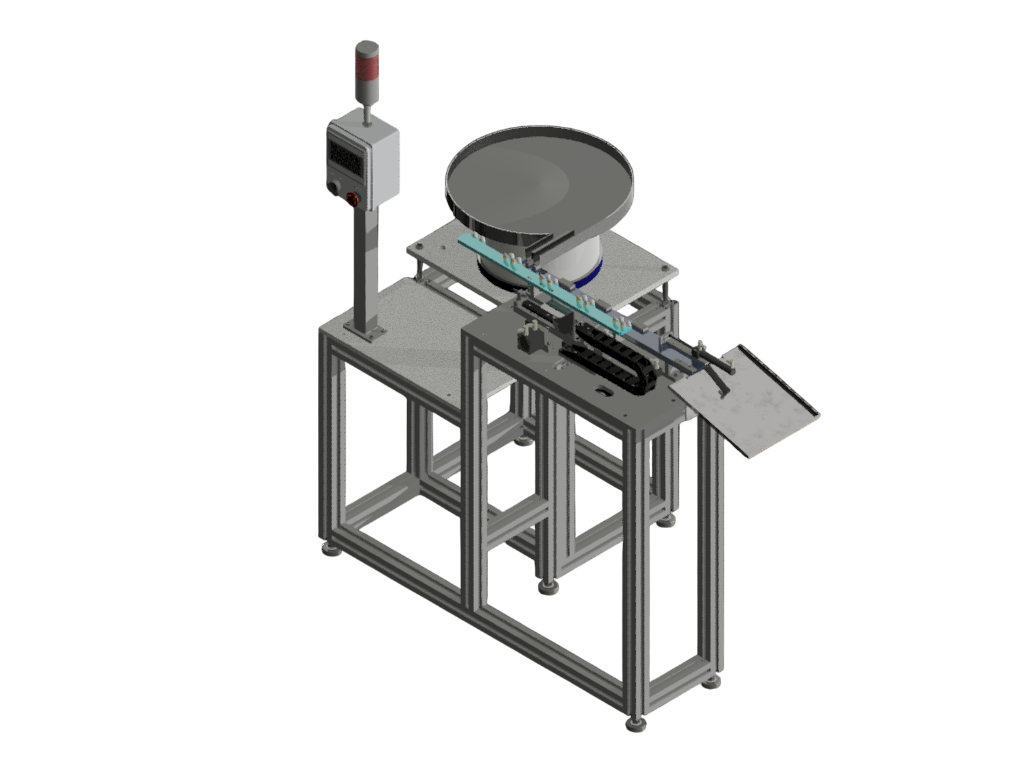

- Automatic speed control possible using a servo motor.

- Using PLC programs.

- Linked with injection molding machine.

Details

| Model | Len-3AL |

| Number of transfer molds | 4 Mold |

| Production capacity | 16 EA/min |

| Program | PLC & Servo Program |

| Power Consumption | 10kW |

🎬Machine Video

PP Assembly & Print Machine

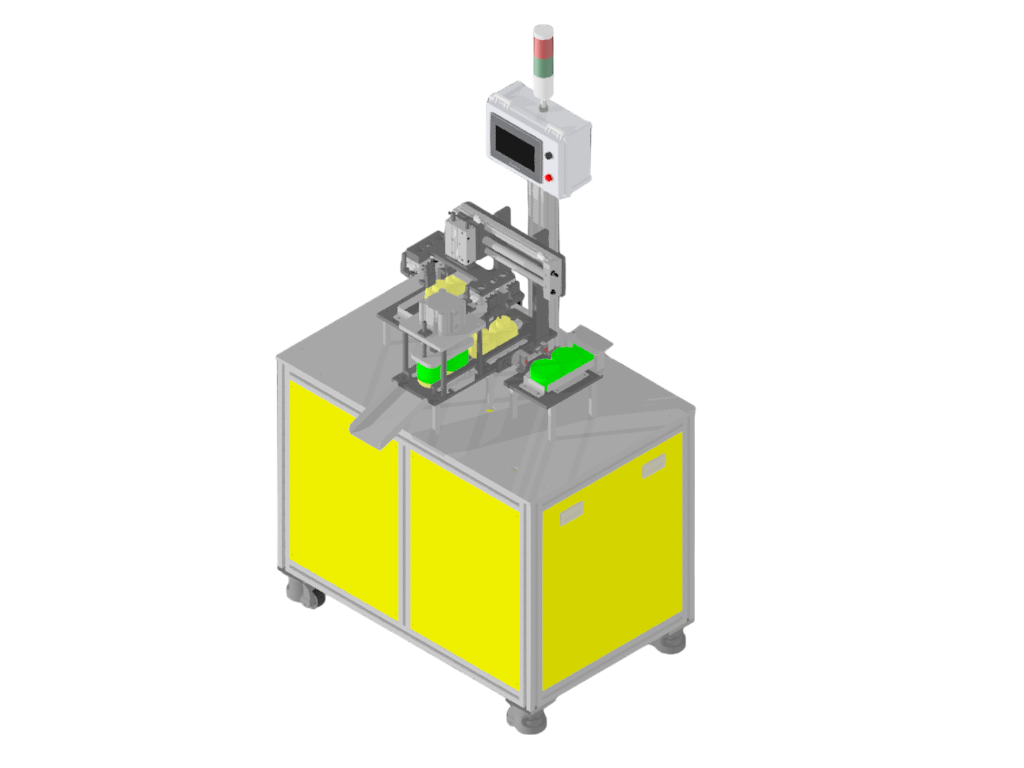

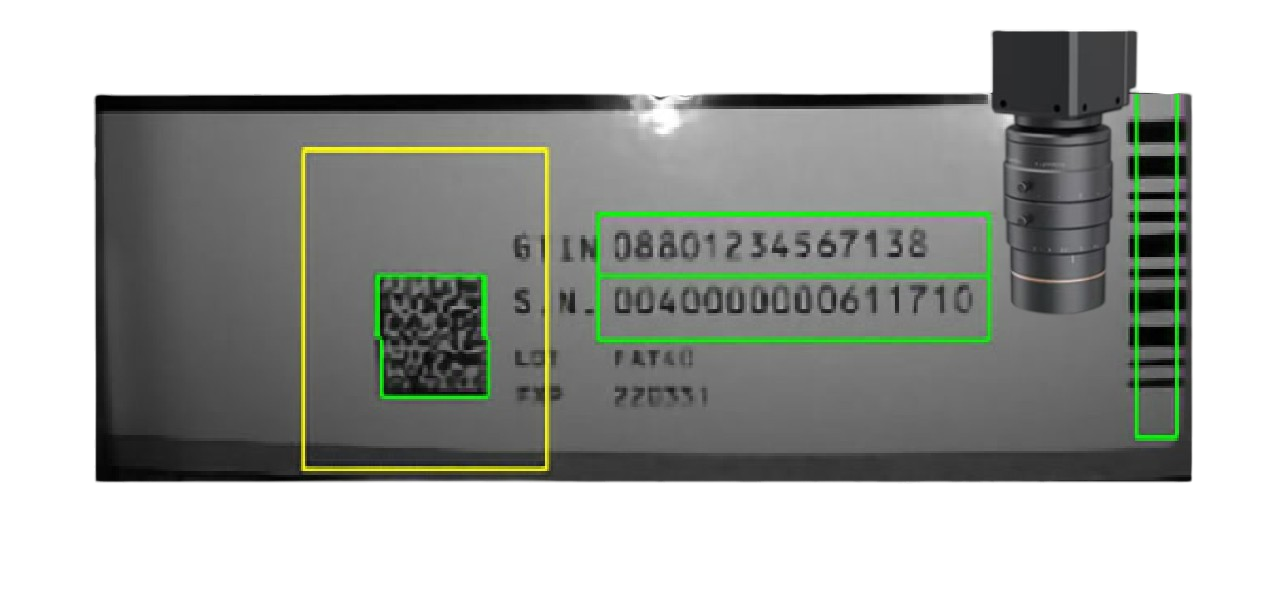

PP Assembly & Print Machine Touch Screen